1:Brief Introduce of K CUP filling machine:

KCUP capsules Filling Machine is the latest Version Machine, High speed and high quality, meet EURO machine standard, this model machine is designed special for Coffee Capsule and K CUP Filling

and Sealing. Its Material use is better than previous machines; Components use top brand.

*stainless steel frame; Organic glass; one columns mold structure; Fixed castor and mobile pulley.

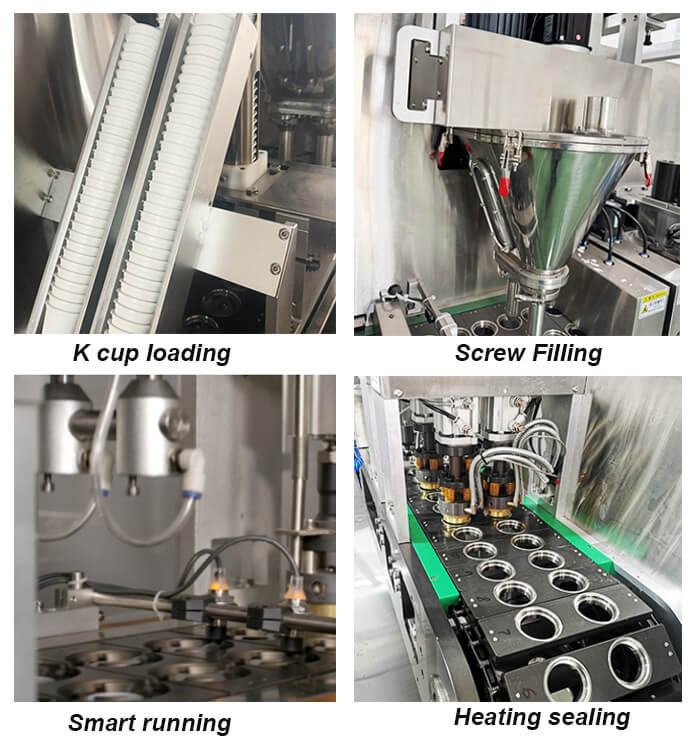

* Coffee servo screw filling, the filling volume can be adjusted on. Touch screen, no cup no filling

*Automatic vacuum suck lids, No cup no Lids suck. Lids suck fault automatic stop.

*Twice Sealing, Omron temperature controller to adjust the temperature.

2:Standard Functions of K CUP capsules filling machine:

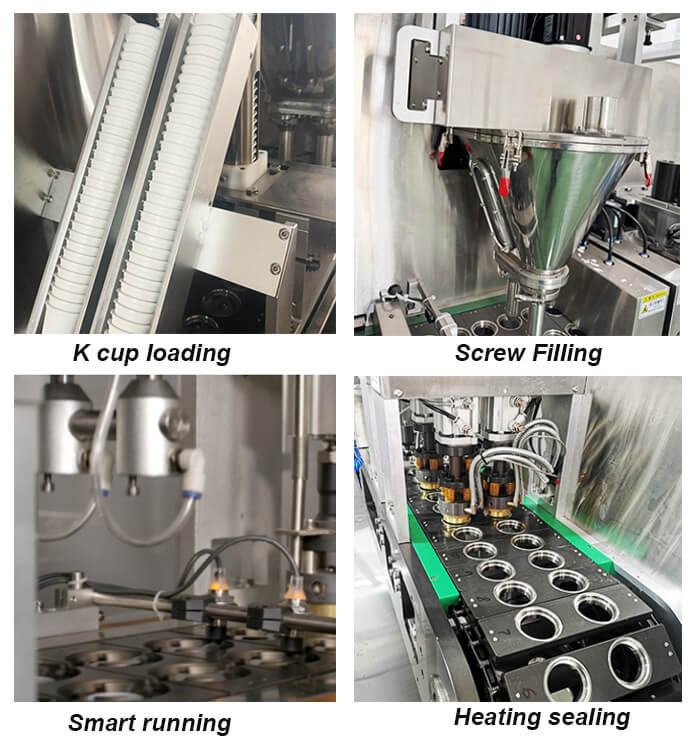

• Vertical cup loading station/Horizontal K Cup loading station.

• Sensors for empty cups and for pre-cut lids: Without a cup, no filling occurs; without a lid, sealing is skipped.

• Servo motor and compressed filling head: Delivers high filling precision, with the compressed filling head pressing the powder during the filling process.

• Nitrogen plate: Comes with a nitrogen connection system that can be directly linked to your nitrogen generator.

• Anti-static features: Minimizes static electricity during filling, thereby reducing dust formation.

• Clean edge handling and powder pressing; secondary sealing and output: The machine automatically applies a second seal on the capsule and ejects the cup.

• PLC controller: Features an English-language interface to adjust machine parameters such as filling volume, sealing temperature, and screw speed.

Optional Functions of K CUP capsules filling machine

• Auger lifter conveyor

• Flavor pump system: This system precisely dispenses 0.01 ml of flavor liquid into each K-Cup in real time.

• Checker weigher system

• Customized conveyor belt and flip-flop mechanism: Automatically counts and transitions to the next box, making it ideal for bulk packaging such as a 96-count box.

• Printer for lot number labeling

• Internet-based remote support

• Paper box packaging machine

3.Machine Features

• High stability: Rational designed Machine can work 24 hours continuously

• High accuracy: filling accuracy is stable at ±0.15g, and very stable working.

•Smart working: machines incorporate a variety of sensors that allows it to detect and smartly decide how to respond to the presence or absence of cups, lids, coffee, air pressure, temperature, position, etc.

•Easy to Use: For extensive control of any internal parameters, the machine features an easy to use touch screen interface (HMI).

• Control system: Industrial Japan PLC controller Omron. Positioning system driven by stepper motors with feedback. Touch screen (HMI) Omron. All in English language. (If you can translate for us, we can put your language inside)

4.Main Working Process Steps

5.Technical parameters of K cup filling sealing machine

|

Model

|

HK-L2

|

|

Suitable product

|

plastic/aluminum/bio Nespresso capsules, Dolce Gusto capsules, K cups, Lavazza capsules, etc.. Pre-cut aluminum foil or Rolled film can be chosen by your side.

|

|

Capacity

|

80-100 K CUPS/min (adjustable)

|

|

Filling type

|

The Servo motor is a driven auger filler

|

|

Filling accuracy

|

±0.1g-0.15g

|

|

Sealing type

|

Pneumatically driven heat and seal, Omron precise temperature controller to adjust

|

|

Voltage

|

3 phase 220V @ 50/60hz - 3kw(by customer)

|

|

Dimension

|

2050mm*670mm*2600mm

|

|

Weight

|

1200kg

|

|

Compressed air consumption

|

≥0.8Mpa/300L per minute

|