Email: mocoffee6@gmail.com Phone: 86 15156153289

|

Model |

HK-R2 |

|

Suitable for |

All powder like coffee powder ,tea powder,mik powder etc different cup package. |

|

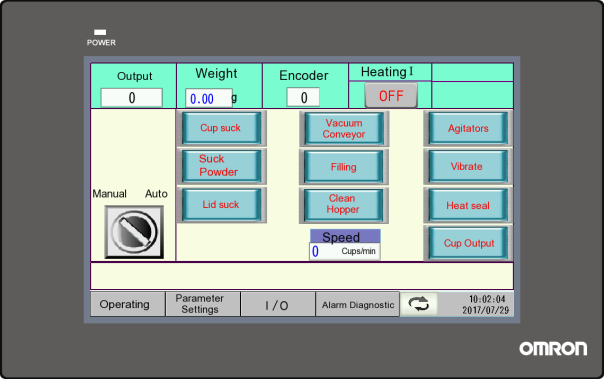

Capacity |

70-80cups/min (adjustable) |

|

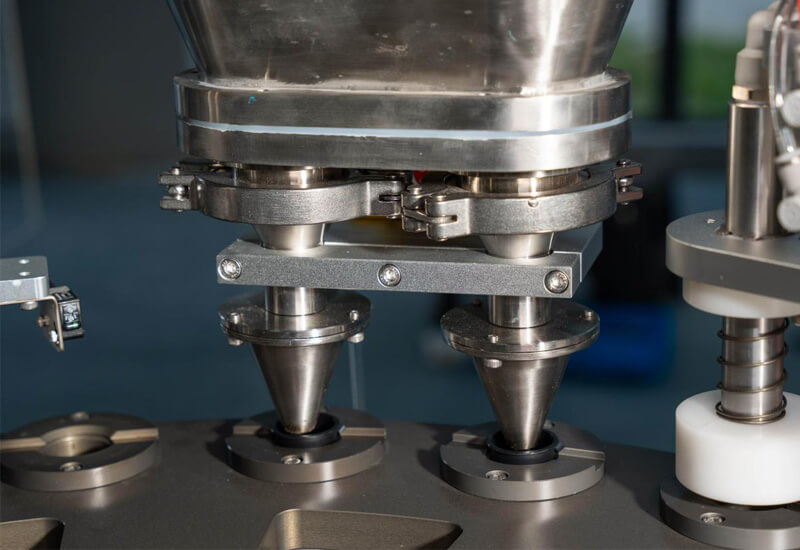

Filling type |

The Servo motor is a driven auger filler |

|

Filling accuracy |

±0.1g-0.15g |

|

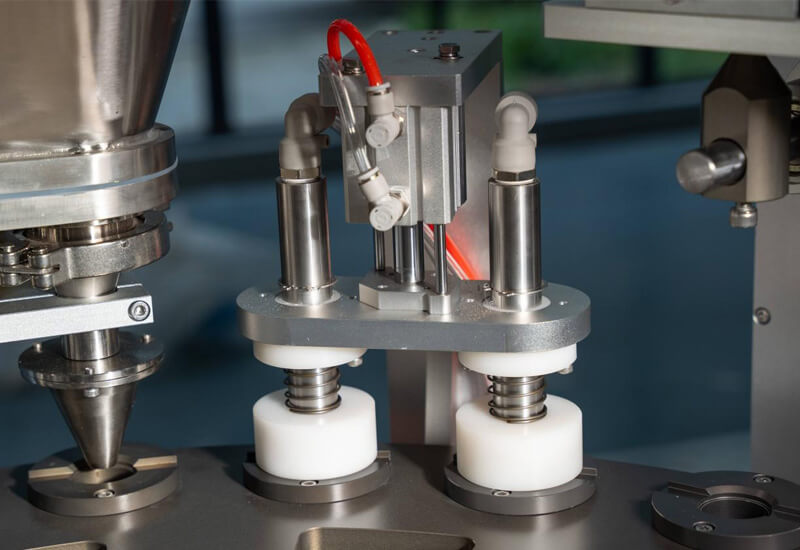

Sealing type |

Pneumatically driven heat and seal, Omron precise temperature controller to adjust |

|

Voltage |

220v 50/60hz—1PHASE (by customer) |

Name: Monica Wu

Mobile:86 15156153289

Tel:86 15156153289

Email:mocoffee6@gmail.com

Add:Floor 1, Hongzhan Road, Xiangyang Town, Xuanzhou District, Xuancheng City, Anhui Province

We chat